Wall sleeves

As an expert in sealing products, we know that a leakproof building entry starts with getting the "hole in the wall" right first time. It is for this reason that we have dedicated several decades to the development of innovative, high-quality and easy-to-use wall sleeves and flange constructions.

We can supply products for installation flush with shuttering, for setting in mortar and for retrofit dowel-fixing. Fixed/loose flange constructions provide a reliable means of integrating bitumen thick coatings or waterproof sheeting, the use of which is prescribed according to DIN 18195 Part 6 for protection against water penetration from the outside or seepage water.

Inserts and flanges / new construction

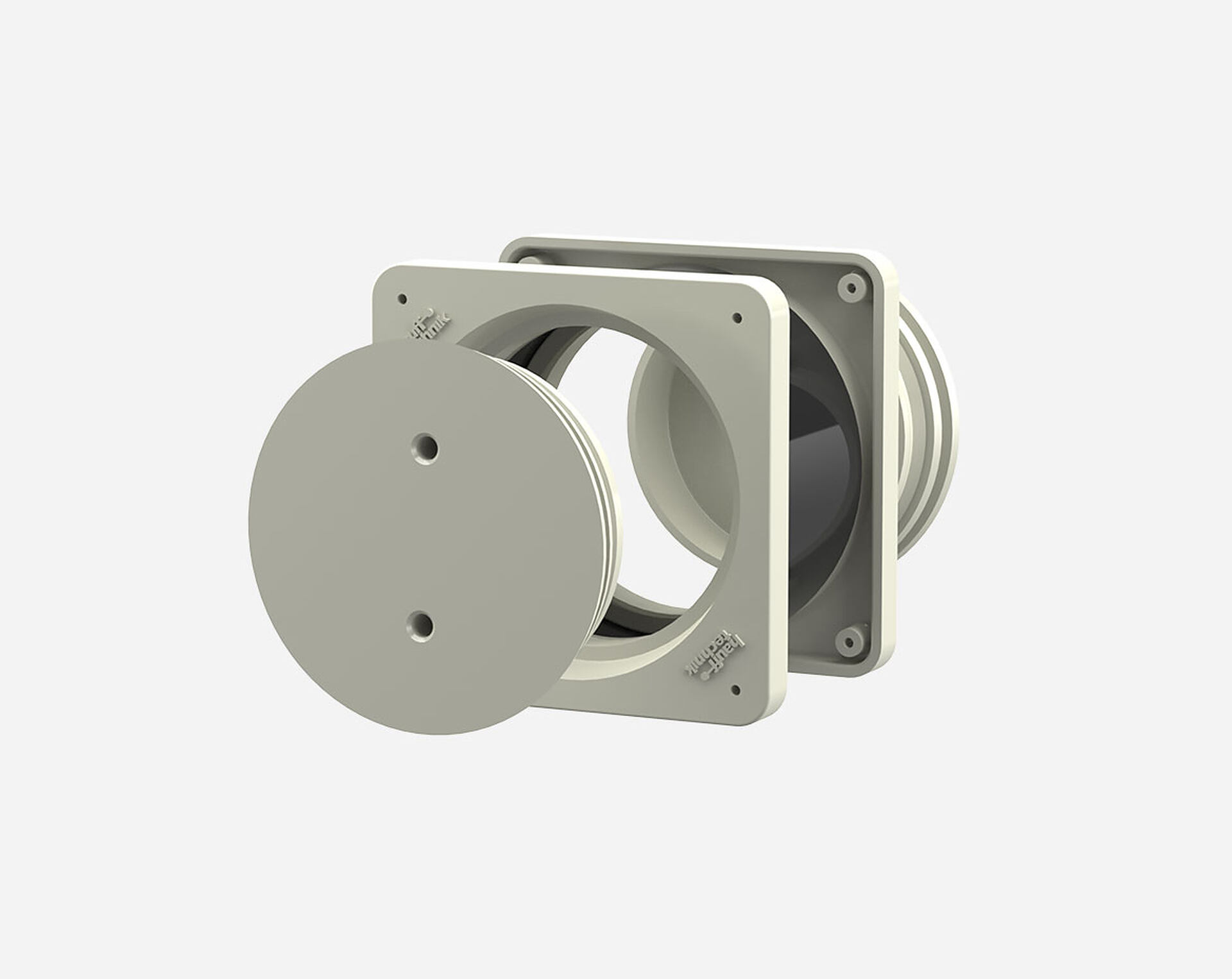

Universal wall sleeve

for any type of wall

UFR

Universal wall sleeve

for any type of wall

UFR B

Cement-coated wall sleeve

with special coating

ZVR

Fibre cement wall sleeve

FZR

Fibre cement wall sleeve

split

FZRG

Connection wall sleeve

AFR 100

Connection wall sleeve

for installation in double walls/element walls

AFRE 100

Bellmouth Wall Sleeve

for setting in concrete

BWS

Cable screw connection

KV PG

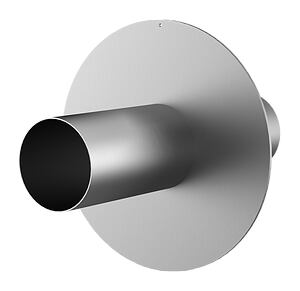

Stainless steel wall sleeve with puddle flange

for setting in concrete

FUM A2

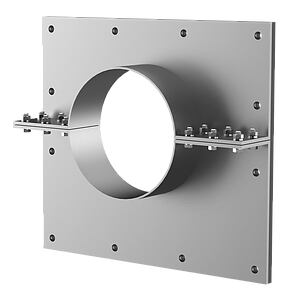

Fixed/loose flange wall sleeve made from stainless steel

for setting in concrete according to DIN 18531*

FLFE DIN18531 A2

Fixed/loose flange wall sleeve made from stainless steel

for setting in concrete for black tank according to DIN 18533

FLFE DIN18533 A2

Fixed/loose flange wall sleeve galvanised

For setting in concrete and connecting bituminous coating

FLFE DIN18533 St-A3CInserts and flanges / subsequent installation

Renovation wall sleeve

SFR

Stainless steel flange

for retrofit installation

FA A2

Stainless steel flange split

for retrofit installation

FAG A2

Fixed/loose flange wall sleeve made from stainless steel

for retrofit dowelling, according to DIN 18531*

FLFA DIN18531 A2

Fixed/loose flange wall sleeve made from stainless steel

for retrofit dowelling for black tank according to DIN 18533

FLFA DIN18533 A2

Fixed/loose flange wall sleeve galvanised

for retrofit dowelling for black tank

FLFA DIN18533 A3CPlan and Implement Empty Conduits – Solutions from Hauff-Technik

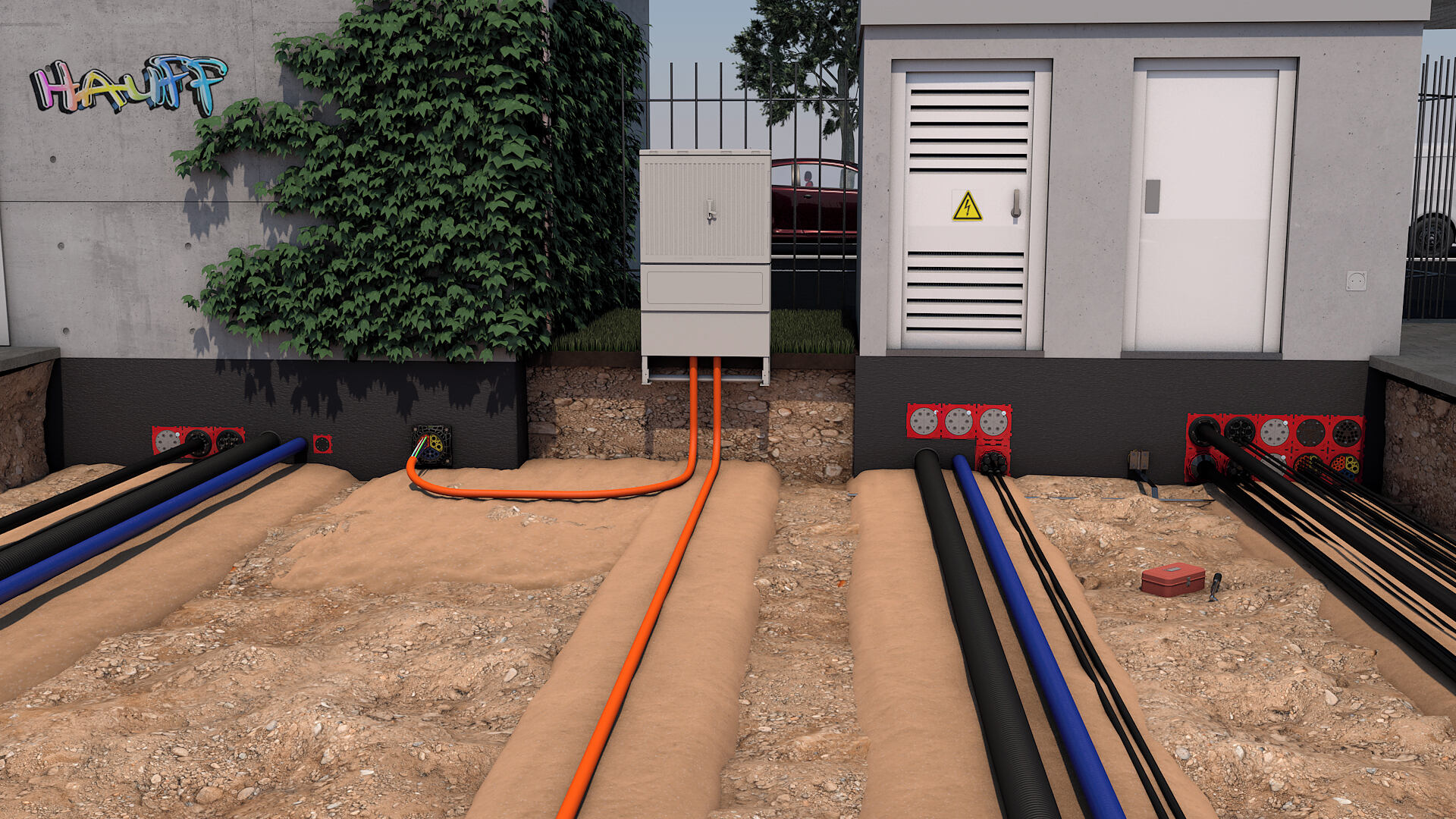

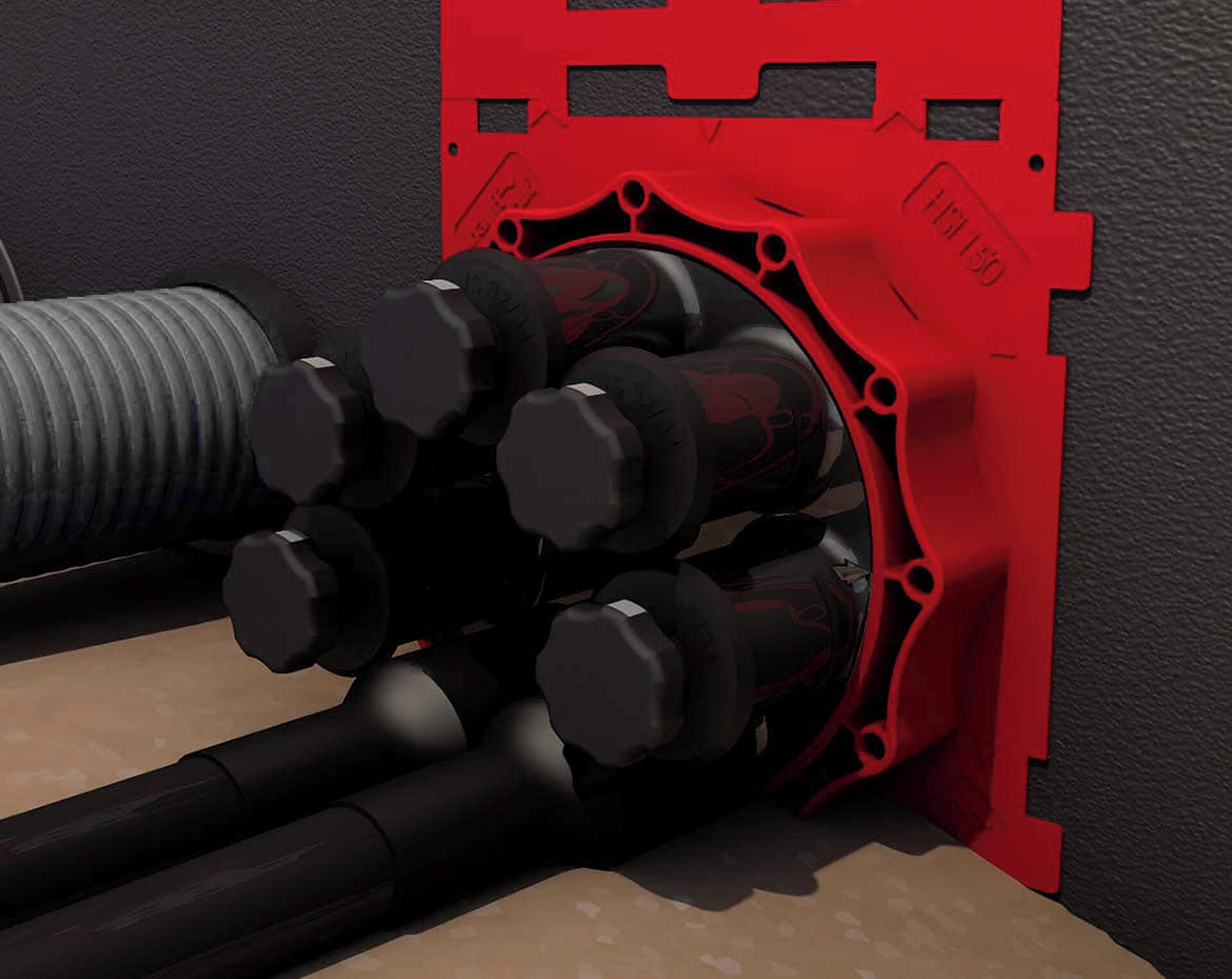

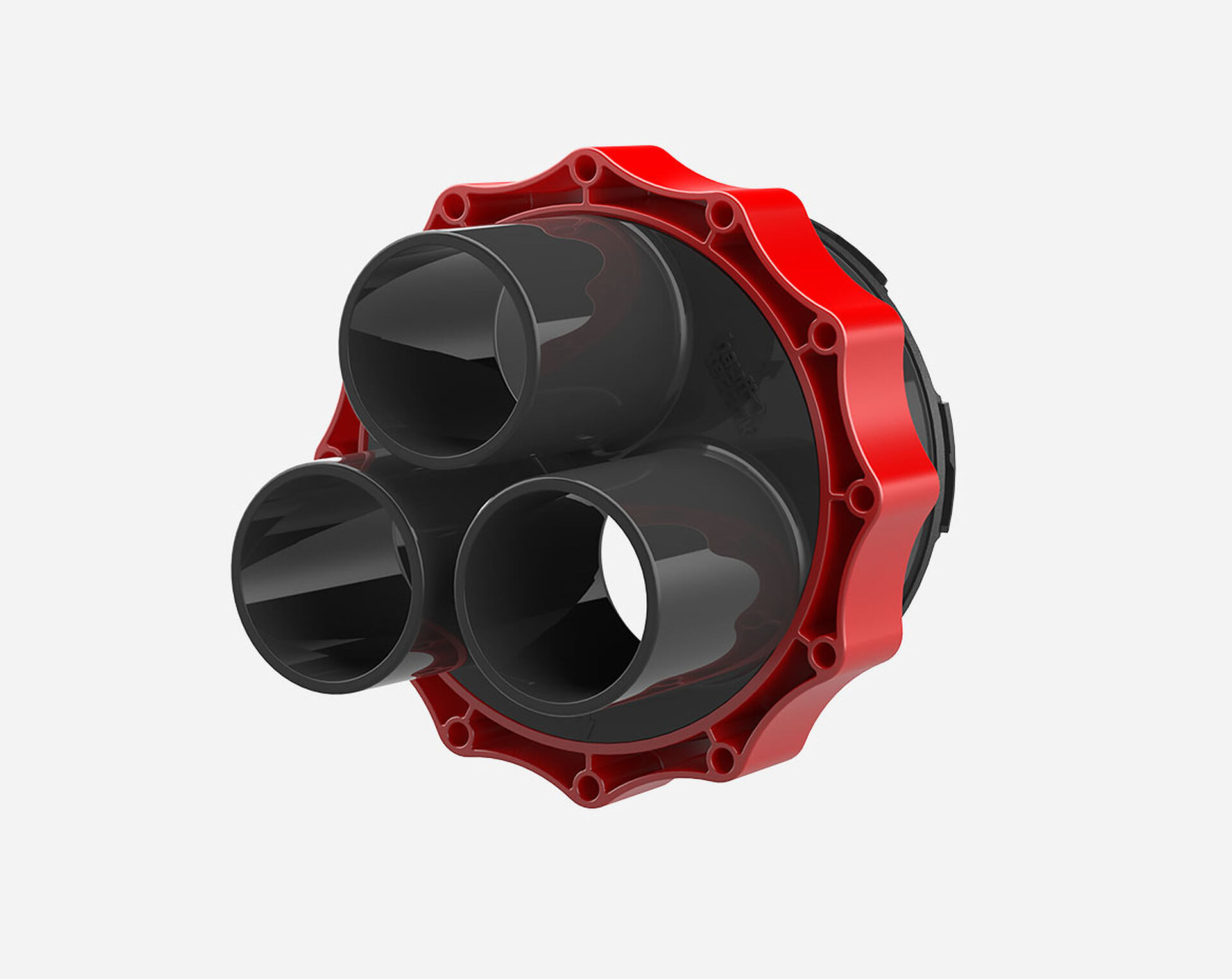

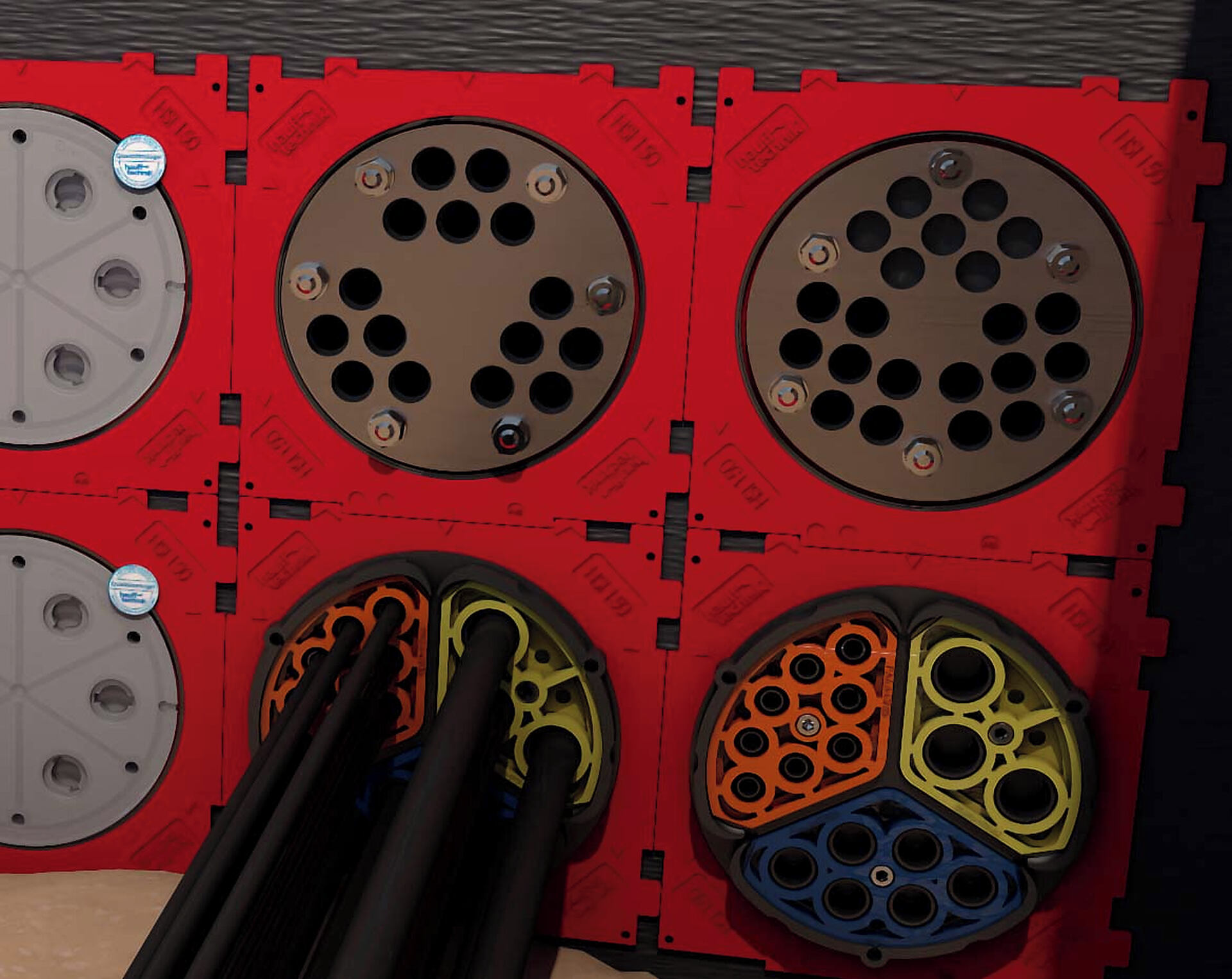

Hauff-Technik’s empty conduits are the ideal solution for future-proofing buildings, allowing for the easy installation of cables and utility lines at any stage. Designed to be installed during the initial construction phase, these conduits provide essential pathways for utilities like power, fibre optics, and water lines. Whether you’re planning for future upgrades or retrofitting a system, Hauff-Technik’s range of empty conduits ensures seamless cable routing. Their products offer robust, gas- and watertight protection, providing long-lasting security for all types of utility installations.

The Advantages of Installing Empty Conduits for Building Services

Planning utility installations with empty conduits is a smart, long-term investment for any building project. These conduits create standardized entry points for utilities like water, power, telecom, and gas. Hauff-Technik offers a variety of empty conduits that can easily be paired with our sealing systems, ensuring professional, watertight, and gas-tight installations for cables of all sizes.

The adaptability of empty conduits is one of their key strengths. Once installed, they provide up to ten service lines through a single conduit, making it easy to add new utilities, such as fibre optics, without additional groundwork. These conduits are suitable for all types of structures, including waterproof concrete walls ("white tanks") and panel constructions.

By installing empty conduits today, you're not just preparing for current utility needs—you’re also ensuring your building is ready for future technological updates, saving on future planning and construction costs.

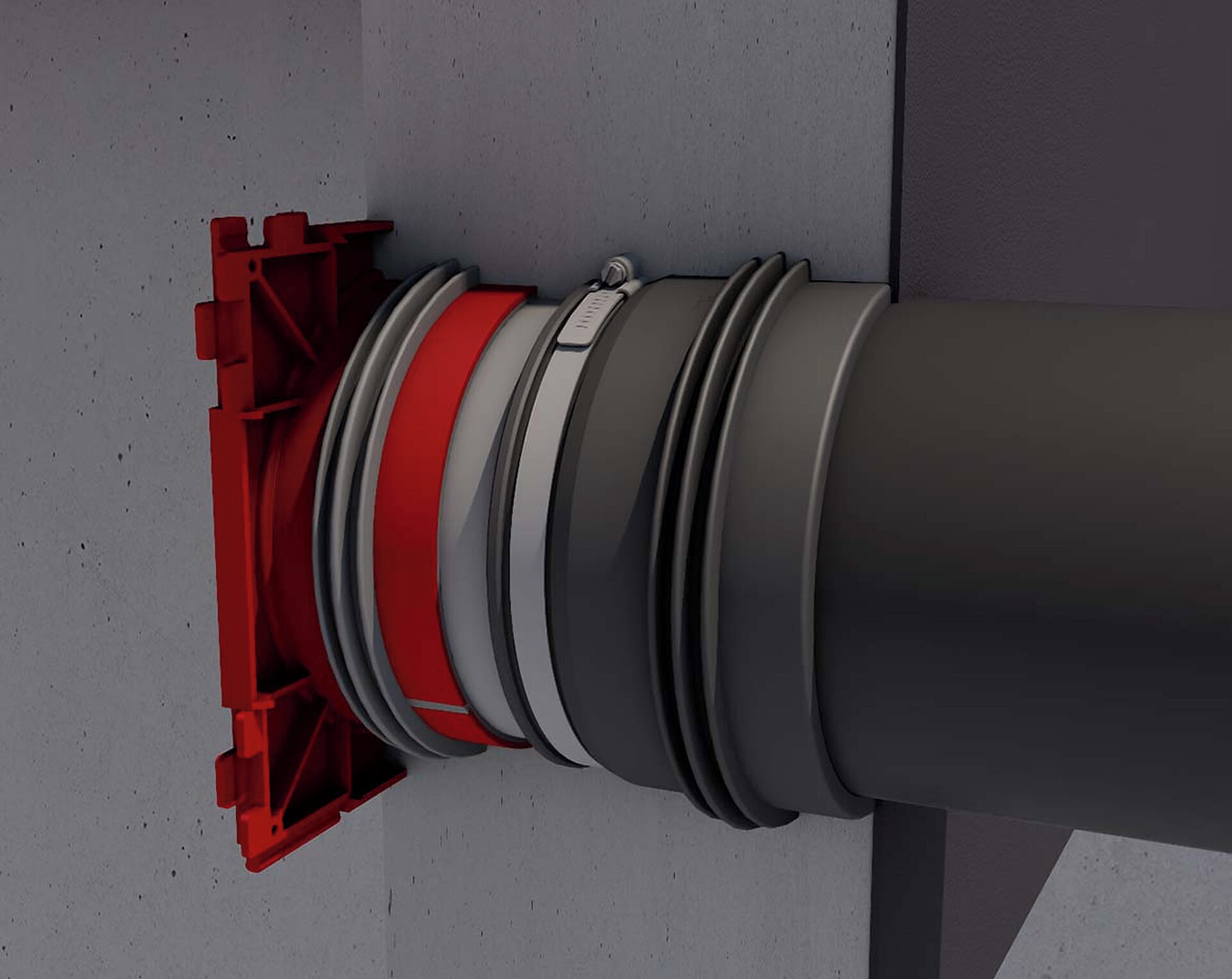

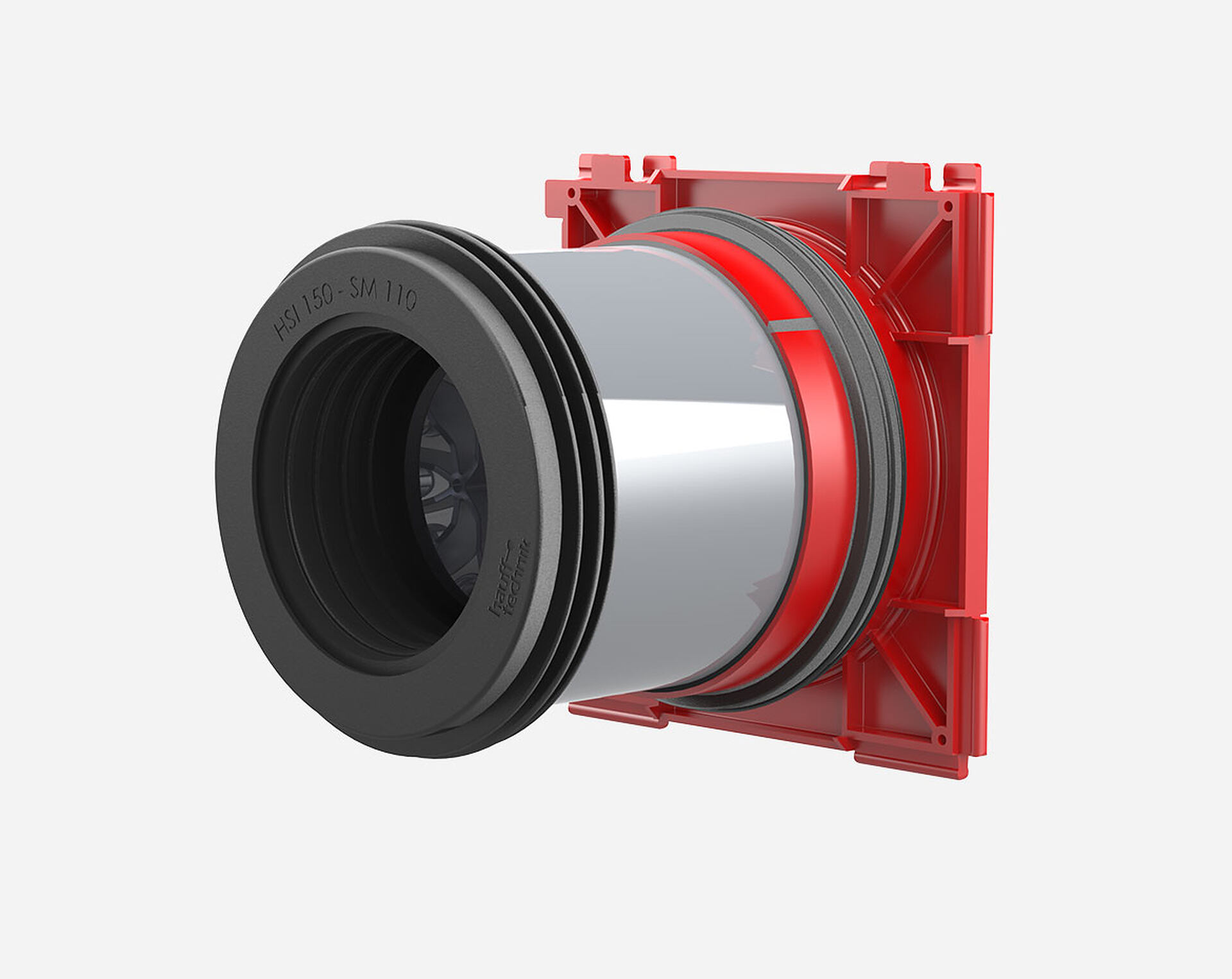

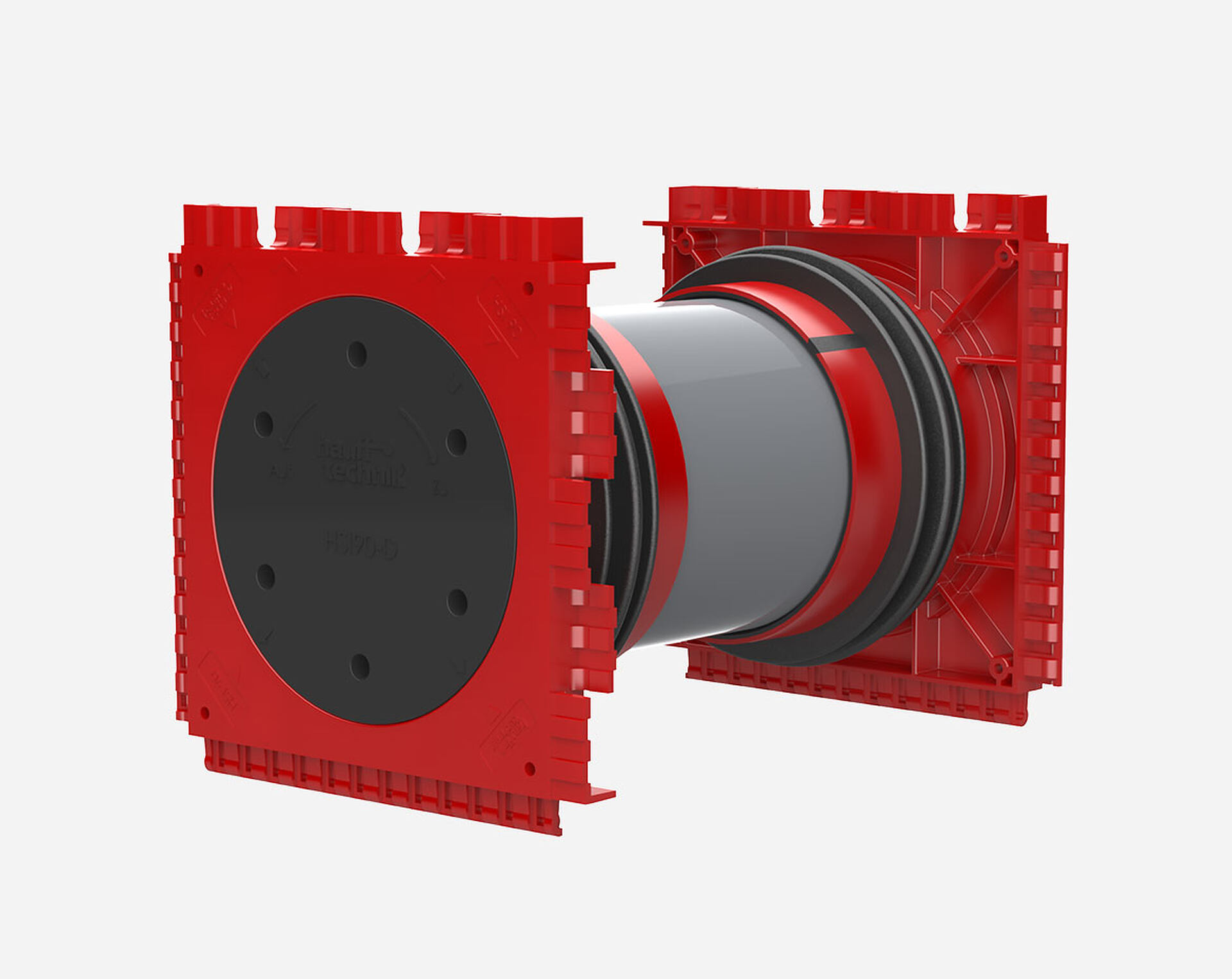

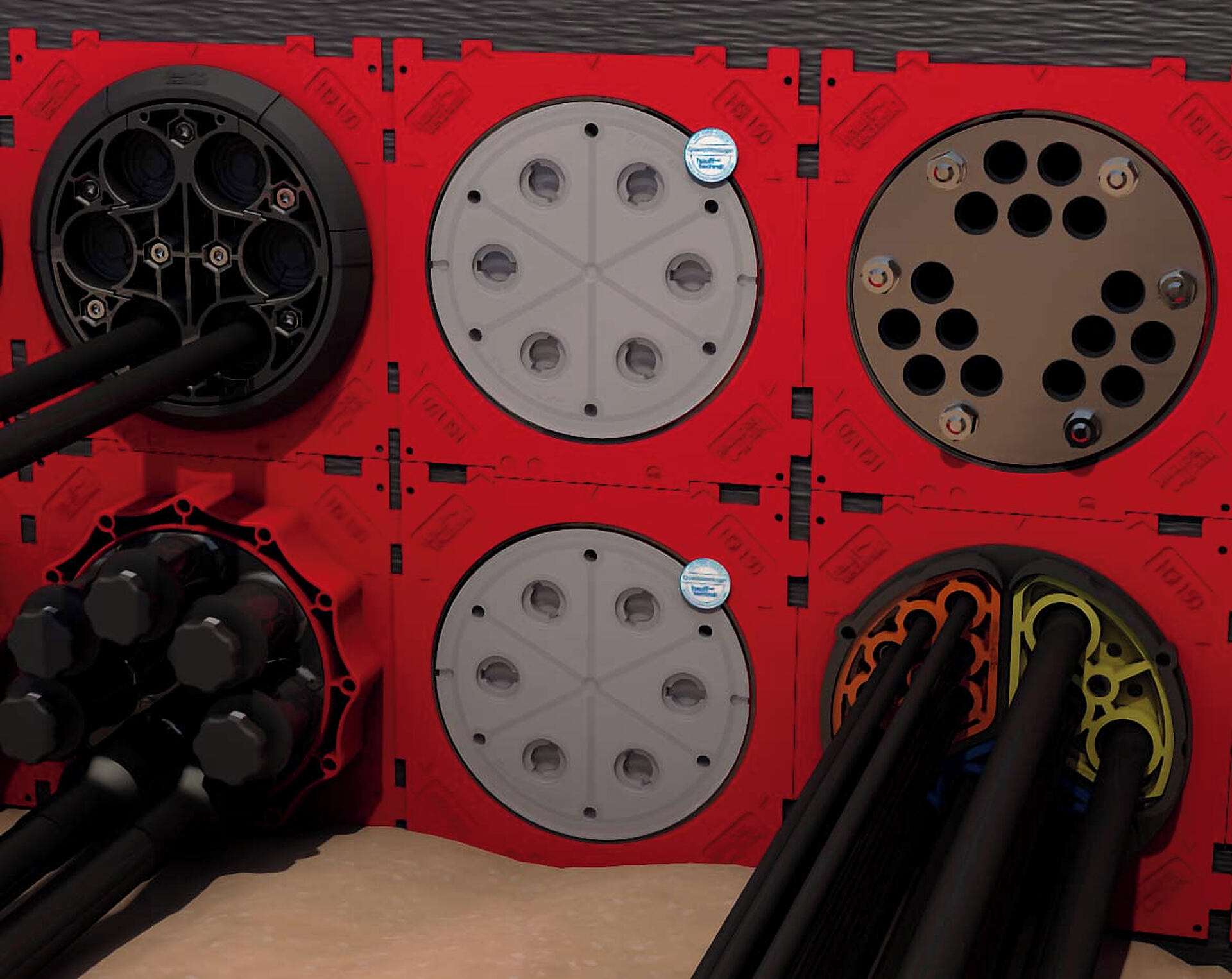

Diverse Solutions for Wall Entries from Hauff-Technik

When it comes to creating cable entries, Hauff-Technik offers a broad selection of options tailored to meet various requirements. Their portfolio includes complete cable entry systems, essential accessories, and customizable empty conduits that can be utilized as needed.

For wall penetrations, Hauff-Technik provides cable entries in diameters of 90 mm and 150 mm. These entries come standard with pressure-tight closing cover, available in angled configurations and with either single or double sealing packs. This flexibility allows you to design a complete system that addresses most cable entry tasks effectively.

Furthermore, Hauff-Technik offers inner pipes (Futterrohre) in different materials, suitable for embedding during the construction process. Options for retrofitting are also available, ideal for situations that require modifications, such as wall breakthroughs.

In cases where existing utility lines are already in place and cannot be separated, Hauff-Technik's renovation pipes come into play. These two-part renovation pipes can easily be installed around existing cables, creating fully gas- and watertight cable entries with the appropriate seals.

Available in lengths from 70 mm to 1,200 mm, Hauff-Technik's empty conduits come in a wide range of diameters, starting from 40 mm up to 900 mm, making them suitable for various installation requirements.

Empty Conduits for Floor Entries

Empty conduits serve as a reliable option for connecting utilities in buildings that lack basements. Typically, the cable entry process is vertical, with a 90-degree angle directed underground towards the street, where the utility line is introduced.

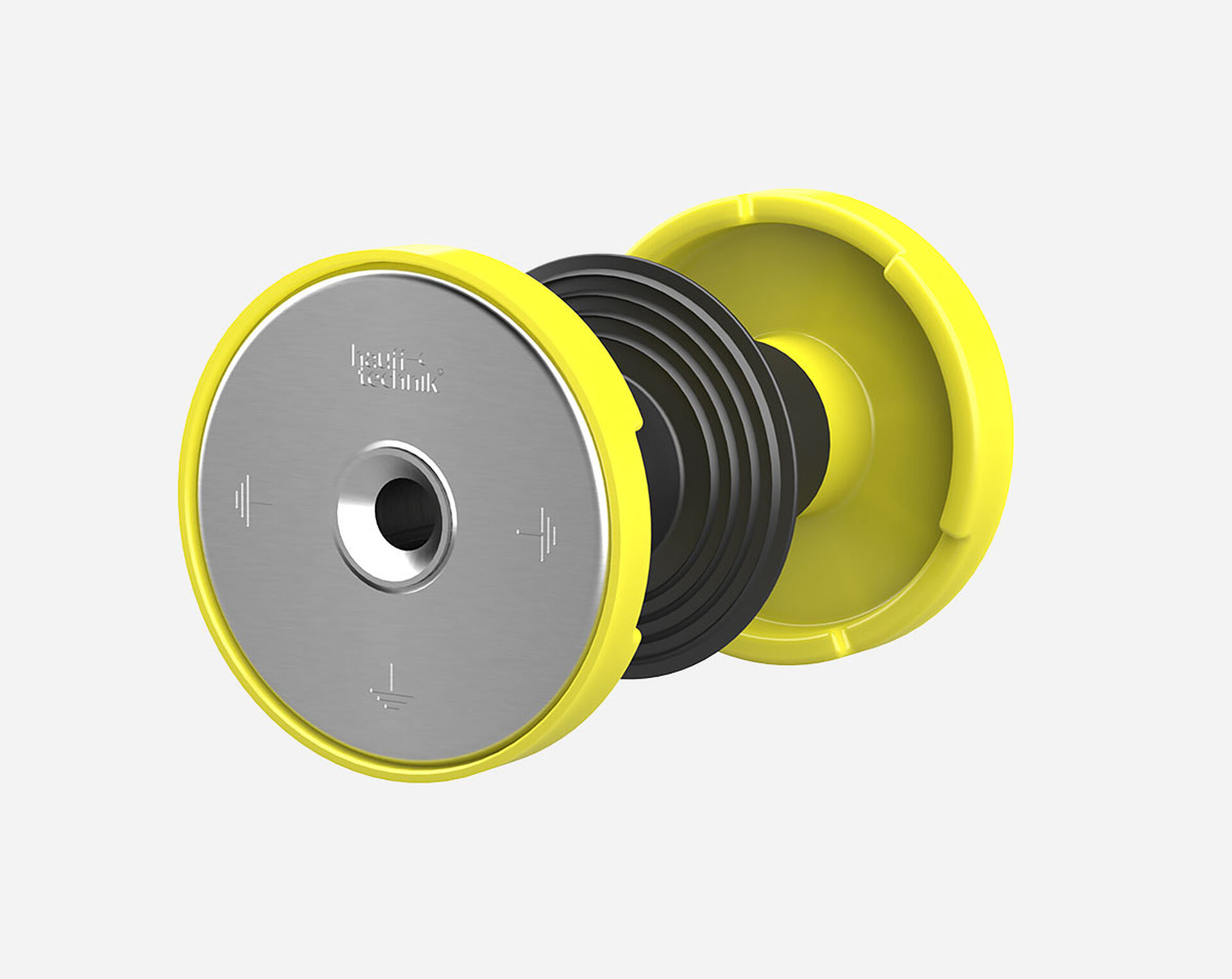

Cement composite pipes with sleeves are the preferred choice for this application. They provide durability and are both gas-tight and water-tight, allowing for direct embedding in the floor slab. The connection to the underground Hateflex spiral hose, which functions as the conduit path, is made using a robust EPDM sleeve. These pipes can accommodate various utility lines in the future. Once installed, the cement composite pipe is cut flush with the floor. Sealing for these empty conduits is effectively achieved with annular seals.

Help us improve our website service.

Where would you place yourself?

Architect & designer

Wholesaler

Telecoms

Utility company

Installer

Construction company

Please choose your region

-

Belgium

Belgium

-

Česko

Česko

-

Danmark

Danmark

-

Deutschland

Deutschland

-

España

España

-

France

France

-

Global

Global

-

Hrvatska

Hrvatska

-

Italia

Italia

-

Luxembourg

Luxembourg

-

Magyarország

Magyarország

-

Nederland

Nederland

-

Österreich

Österreich

-

Polska

Polska

-

Schweiz

Schweiz

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Global

Global

-

USA

USA

-

Global

Global

-

India

India

-

中国

中国

-

Global

Global

-

الإمارات العربية المتحدة

الإمارات العربية المتحدة